RESEARCH TRIANGLE PARK, N.C., June 9, 2010- Fl studio 11 registration key free. Geomagic has released new versions of its 3D software for reverse engineering and quality inspection: Geomagic Studio 12 and Geomagic Qualify 12. The new releases bring unparalleled ease of use to the market for 3D scanning software, along with new features that improve results and save time.

Simpler, faster, more compatible

RESEARCH TRIANGLE PARK, N.C., April 29, 2009-Geomagic announces Geomagic Studio 11, featuring Parametric Exchange that establishes an intelligent connection between scanning and CAD, and a range of enhancements that streamline every aspect of the 3D modeling process.Geomagic Studio 11 will begin shipping on May 4 and is making its public debut next week in the Geomagic booth at Control 2009 in. Tutorial control 3,508 views. Geomagic Studio, Geomagic Qualify, Geomagic Qualify Probe, Geomagic Spark and “the magic of making it simple” are.

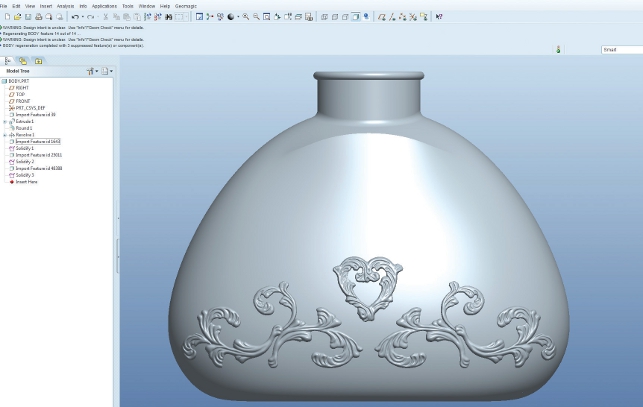

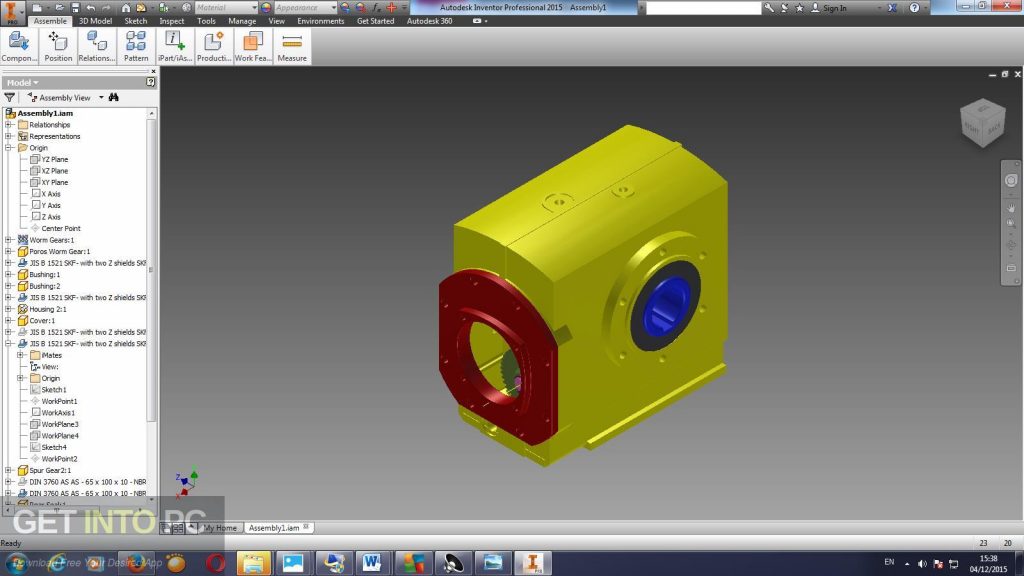

Sly cooper pc game free download. Geomagic Studio 12 directly integrates with leading 3D mechanical CAD packages, allowing users to quickly and easily create parametric CAD models from 3D scan data. Geomagic Qualify 12 includes an entirely new report generation and publishing engine that enables colorized and annotated 3D models to be embedded directly in PDF.

Both applications offer the familiar ribbon-style interface pioneered by Microsoft in Office 2007, support for Windows 7, and optimizations that speed up runtime by up to 40 percent.

Geomagic Studio 12 represents a leap forward for Robb Rudluff, design engineer at pHluid, which provides engineering services that speed product development and improve quality for customers such as Quatro Composites, Edwards Lifesciences, G&G Motorsports, Yamaha Motor Corp. and others.

'The new ribbon interface makes it simple to access the comprehensive features of Geomagic Studio 12 - they're all right in front of you in a left-to-right layout,' says Rudluff.

Fastest path from points to CAD

Parametric Exchange - the exclusive Geomagic feature that enables parametric models created in Geomagic Studio to be transferred directly into 3D CAD software - has been significantly upgraded and expanded.

'The ability to automatically trim, join, cut or subtract surfaces and solids in Geomagic Studio's Parametric Exchange further streamlines the process of turning scan data into fully parametric, native-format CAD models that my customers can put to immediate use,' says Rudluff.

New features in Geomagic Studio 12 that optimize the reverse enginnering workflow include:

- Automatic surface and solid trimming via Parametric Exchange, leading to faster creation of full-fidelity CAD models.

- Enhanced Autosurface capabilities that reliably convert polygon meshes into exact NURBS surfaces with one click.

- More flexible workflows to support faster design iterations.

- Fast and intuitive hole-filling and improved automatic 'healing' of polygon meshes.

Ease of use, groundbreaking reporting

Geomagic Qualify 12 quality inspection software is called a 'major step forward' by Rus Emerick, who leads 3D imaging implementation at Schneider Electric, a global specialist in energy management with operations in more than 100 countries and sales of 15.8 billion euros in 2009.

'The grouping of functional commands under tabs and sub-modules in the new GUI provides an efficient, process-oriented workflow,' says Emerick. 'The improved Automation Designer enables users to easily create, edit and store a part's unique verification and inspection process for use on current and future parts, ensuring all versions are inspected in an identical manner.

'But, the real bonus in Qualify 12 is the 3D PDF generator, which places an interactive 3D object in the report, enabling anyone with Adobe Acrobat to view and manipulate it. This capability delivers tremendous collaboration power for quality analysis teams throughout the enterprise.'

Other new features in Geomagic Qualify 12 include quick feature creation to speed up the creation of inspection plans and new algorithms for aligning test models with reference models.

Available now

Geomagic Studio and Qualify 12 are available immediately. They ship with both 32- and 64-bit editions on the CD, and support English, German, French, Italian, Spanish, Chinese and Japanese. Visit www.geomagic.com for more information and to sign up for free trial versions of Geomagic Studio 12 and Geomagic Qualify 12.

Geomagic Studio 12 Tutorial Download

About Geomagic

Geomagic (www.geomagic.com) is a global company dedicated to advancing and applying 3D technology for the benefit of humanity. Geomagic’s scanning and design software solutions are used to capture and model 3D content from physical objects, organically sculpt complex shapes, and prepare products for manufacturing. In addition, the company produces powerful 3D metrology and inspection software that verifies dimensional quality by comparing as-built products to master designs. Geomagic’s Sensable Phantom haptic devices simulate the sense of touch in a digital environment.

Geomagic’s software and hardware are utilized by world-class customers in a variety of industries, including aerospace, automotive, medical, consumer products, toys, collectibles, coindesign, jewelry, fine art, heritage restoration, research, education, mold making, entertainment, training and surgical simulation. In fact, some of the world’s leading companies and research organizationsuse Geomagic software, including Ford, BMW,Boeing, Harley Davidson, Timberland, Mattel/Fisher Price, Lego, Pratt & Whitney, NASA, Schneider Electronic, 3M, Danaher and Invisalign. Geomagic is based in Research Triangle Park, N.C., USA, with an office in Boston, subsidiaries in Europe and Asia, and channel partners worldwide.

###

Geomagic, Geomagic Studio, Geomagic Qualify, Geomagic Qualify Probe, Geomagic Spark, Wrap, Geomagic Wrap, Phantom, OpenHaptics, Omni, Freeform, Claytools, Sensable and Sensable Technologies, Inc. are trademarks or registered trademarks of Geomagic Inc. All other trademarks are the property of their respective owners.

Geomagic Studio 13

Media Contact:

Rachael Taggart

Geomagic, Inc.

+(1) 919-474-0135

Contact Rachael

Download Geomagic Studio 12 and Geomagic Qualify 12 full crack forever

Link download Geomagic Studio 12 32bit 64bit full license

Geomagic Download

Link download Geomagic Qualify 12 x86 x64 full crack

Working with Geomagic Studio 12 full

Working with Geomagic Qualify 12 full

Geomagic Studio 12 Tutorials

Geomagic Studio – a software package that provides extensive opportunities for reverse engineering, allowing you to create a surface model of the object on digitized data. The package differs from others in its ease of operation and training, an intuitive interface and high speed with large data volumes (up to 100 million points). The support of multiprocessor computing systems is realized. It supports interaction with almost all scanners and 3D digitization devices, as well as import of digitization data of various formats.

The program implements the ability to combine several point clouds into one. The program Geomagic Studio has a large number of tools for cleaning the array of data from “noise” (mistakenly digitized points), reducing the number of points by thinning and ordering, taking into account the curvature. There are ample opportunities for creating triangulated surfaces, filling holes in them taking into account the curvature of the surface.

There are tools for editing polygons, smoothing, applying logical operations (intersection, union, subtraction) and drawing text. The program automatically determines the planes, cylinders, axes, round and rectangular holes and grooves. Geomagic Studio allows both manually and completely automatically, to create NURBS surfaces. There are tools for determining flat surfaces, as well as for intersecting the resulting surface with planes. There is the possibility of analyzing the curvature of the surface, comparing it with the initial point cloud to assess the quality of the model construction.

The Geomagic Studio software package includes the ability to automate processes using templates and macros, as well as writing native programming modules in Visual Basic, C, C ++ or Java.

The resulting triangulated and NURBS surfaces are exported to any CAD system, design and animation programs for further use.

Geomagic Qualify is a metrological software that allows you to make the process of checking the quality of manufacturing products in modern production more detailed and quick. The package differs from others in its ease of operation and training, an intuitive interface and high speed of operation. The support of multiprocessor computing systems is realized. It supports interaction with almost all scanners and 3D digitization devices, as well as import of digitization data of various formats.

In the program it is convenient and understandable to realize the possibility of controlling linear and angular dimensions both on the plane and in space, as well as deviations of the shape and mutual arrangement of the surfaces in accordance with the requirements of the drawing. The program has a large number of tools for working with point clouds and CAD-models, for their combining and graphical comparison in the form of a color palette of deviations.

Geomagic Qualify allows you to easily and quickly create various types of reports, from the simplest to the most detailed. Also, the program has a powerful automatic reporting function, which allows you to save a large amount of time spent working out the results. Various report formats, such as HTML, PDF, MS Word, MS Excel and CSV, allow you to meet all the requirements for registration issued by the customer.

The Geomagic Qualify software package includes the ability to automate processes using templates, macros, and writing native program modules in Visual Basic, C, C ++, or Java. This allows for automated control of batches of parts with the possibility of subsequent statistical analysis of the information received (SPC). There is a special module that allows automatic control of the geometry of turbine blades with the calculation of sizes in characteristic sections and the subsequent creation of a report.

Extras. Information: Functional description:

* Basic elements and characteristics:

O planes, axes and points

O openings round, elongated and rectangular, edges

O automatic creation of basic elements and characteristics of the CAD-model

* Combination:

O by reference base elements and characteristics

O RPS (Base Point System)

O according to rule 3-2-1

O best approximation method

O use of transformation matrices

* Three-dimensional analysis:

O color maps of deviations

O Distribution histograms and adjustment of the color scale of deviations

O deviation beyond tolerance

O showing the values of deviations at given points with the help of labels

* Two-dimensional analysis:

O analysis of deviations in cross sections

O analysis of boundary edge deviations

* Measurements:

O volumetric measurements on basic elements and characteristics

O measurements of angles and distances in characteristic sections

O automatic calculation of dimensions in cross sections that determine the aerodynamic properties of turbine blades

O control of the shape and surface tolerances

* Creating reports:

O formats: HTML, PDF, MS Word, MS Excel and CSV

O Reporting in 3D using VRML

* Automation:

O Full automation of the processes from data loading to the creation of reports

O Using templates to control the batch of parts

* Instruments:

O screen snapshots with a single mouse click

O mirroring / scaling / copying

* Processing of large data sets:

O intelligent memory management

O Multi-threaded operations for multiprocessing

O batch processing of data

* Work with points and polygons:

O a sample taking into account the curvature of the surface

O point shift to compensate for the thickness of the part

O removal of disturbances (erroneous points) with display of deviations

O the creation of points from a triangulated surface

O decrease in the number of points (thinning out)

O Smoothing and averaging points

* User interface:

O customizable toolbars, convenient and detailed drop-down menus, and also “hot keys” for frequently used commands

O user-customizable program color themes

O floating panels and windows

O Macro commands created by the user

O context-sensitive help

* Developer tools:

O built-in command set (API) for equipment management

O Ability to write your own program modules using languages such as Visual Basic, C, C ++ or Java

Importing files:

* Formats for importing the results of digitization:

O 3PI (ShapeGrabber); AC (Steinbichler); ASC (ASCII common format); BIN, SWL (Perceptron); BRE (Breuckmann); CAM, CDK, CDM, VVD (Minolta); CWK (Kreon); COP (Pulsetech); DBT (Digibotics); DPI (Dimensional Photonics); G3D, SURF (GOM); GPD, MGP (Geomagic); GTI (Genex); HYM (Hymarc); ICV (Solutionix); MET, MTN (Metron); NET (InSpeck); OPT (Open Technologies); PIX (Roland); PMJ / X (3D Digital); SAB2 (3D scanners); SCN, PCN (LDI / Datasculpt); XYZ (Opton); XYZN (Cognitens)

* Import / export of polygonal models:

O 3DS, DXF, IGS, LWO, NAS, OBJ, PLY, STL, VRML, WRP

* Import of CAD-models:

O IGES, STEP 203/214, Neutral, VDA, Pro / E PRT, SAT, Parasolid .x_t and .x_b

* Translators:

O CATIA V4 and V5

If you want this softs, click download and check out a little bits to support this web, the download link automatically appear after your payment completely.

Any problems, contact admin for supports: clickdown.org@gmail.com

Thanks all